Sewage Treatment Plant & Waste Water Treatment Plant

Leading Manufacturers, Exporters, Wholesaler, Retailer of Aluminum Slug Gate, Bar Screen, Butterfly Valve, Fine Screen Mat, Manual Bar Screen, Mechanical Bar Screen, Mechanical Fine Bar Screen and Screw Conveyor from Ahmedabad.

| Business Type | Manufacturer, Supplier |

| Length | 2000 mm |

| Height | 900 mm to 750 mm |

| Width | 20mm |

| Screw Height | 100 mm |

| Gate body material | SS |

| Gate Material | SS |

| Transmission | Manual / Automatic |

| Business Type | Manufacturer, Supplier |

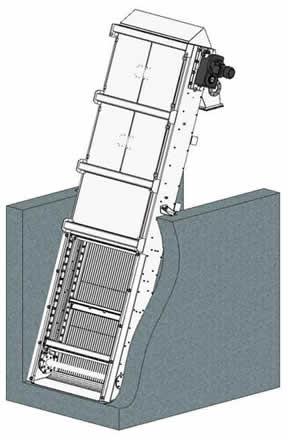

| Overall length | 2000 to 12000 mm |

| Discharge height from channel bottom | 1100 to 9780mm |

| Discharge length | 1150 mm |

| Screen width | 430 to 2030mm |

| Effective width | 350 ? 1950 mm |

| Discharge height from operation floor | 400 to 6800 mm |

| Overall height | 1820 to 10500mm |

The bar screen starts and stops automatically according to the water level difference between upstream and downstream by means of level sensor or by timer clock. The bar screen includes a screen frame, a bar rack (grid) a back dead plate, a series of chain driven rakes and a drive unit. All bearings and critical parts are above liquid level at all times to facilitate lubrication and improve machine life. The number of rakes de? pends on the screen length and type of effluent. When the screen is started, the 2 chains on the sides pull the rakes towards the top of the screen. When passing in between the bar rack, the rakes collect the screenings waste and lift them to the top where an ejector system pushes the screenings waste into the conveying or compacting system. The bar screen is a mechanical fully automatic screen used for liquid/solid separation in the pre-treatment stage of wastewater treatment plants, pumping station, Sewage treatment plant, etc

| Business Type | Manufacturer, Supplier |

| Nominal pressure | PN16, PN25 |

| Medium Temperature | 10°C~ +110°C Maximum |

| Body Material | 210, FG 220 CI |

| Stem Material | ASTM A276, GR SS 410 |

| Disc Material | Epoxy Coated Ductile Iron Disc |

| Lever | CRCA SHEET |

| Leakage Rate | No visible leakage |

| Medium Type | Water |

| Flange standard | IS 1538 |

| Shell Test pressure | PN16-24bar/PN25-37.5 bar |

| Seal Test pressure | PN16-17.6bar/PN25-27.5 bar |

- Wide Size range

- Operated by Lever or Gear Box.

- 90 deg opening/closing operation.

- Cast iron Body with powder coating.

- Epoxy Coated Ductile Iron disc.

- Wafer type Connection

| Business Type | Manufacturer, Supplier |

| Size | 18x12feet, 20x14feet |

| Material | Natural Rubber |

| Shape | Rectangular |

| Thickness | 9-12mm |

| Application | Industrial |

| Feature | Anti Slip, Durable |

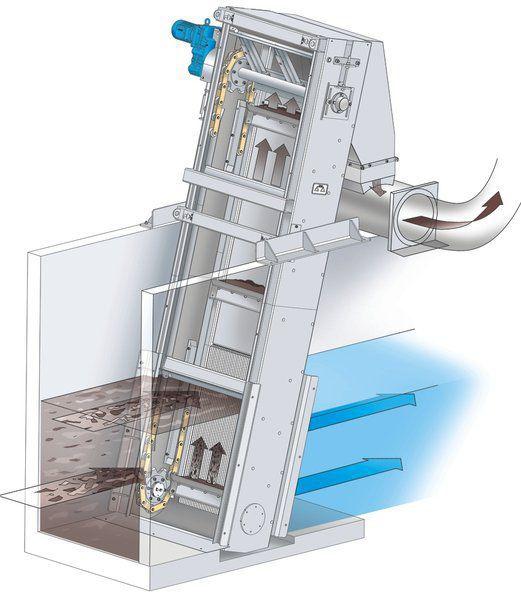

Fine screening is the second mechanical pre-treatment process allowing finer separation than coarse screens of the solid waste contained in the raw water. Filtration is carried out by a 6 mm to 0.25 mm opening using perforated sheet or wedge wire. Fine Screens are most of the time automated thanks to a motorization of the system of collection by a spiral, screw, drum, scraper or conveyor table. Manual solutions also exist requiring the action of an operator for a more affordable cost. The solid waste can then be discharged into a compaction system allowing a reduction in weight / volume and optimal dryness. The Fine Screen widely used in municipal wastewater treatment plant, pre-treatment device for domestic effluents, municipal rainwater & sewage pump station, water intake of water supply plant & cooling water of power plant. It can also be used for industrial wastewater treatment, such as textile, printing and dyeing, food, fisheries, paper making, brewing, slaughtering, and tanning industry. It is regarded as the ideal solid-liquid separation equipment in the water treatment field.

- The driving device is under the drive of cycloidal pin gear speed reducer or helical gear reducer, with low noise, neat structure & stable operation.

- Integrated framework, with good rigidity and convenient installation and maintenance.

- Two specifications for rake tooth, pitch t=150mm for coarse screens, pitch t=100mm for fine screens.

- Easy to operate. It can be direct or remote controlled. Mechanical shearing bolt & over-current protection are set to ensure safe running.

- While the width of equipment over 1500mm, parallel machines are adopted to ensure the integrated strength of equipment.

| Business Type | Manufacturer, Exporter |

| Material | Stainless Steel |

| Driven Type | Manual |

| Color | Metallic, Silver |

| Application | Liquid Separation |

| Feature | Corrosion Resistant, High Quality, High Strength, Long Life |

| Voltage | 380 V |

| Type | Manual Bar Screen |

| Country of Origin | India |

- The Manual Bar Screen is used to screen sewage water entering the purification plant, and is normally installed in channels.It is composed of a set of filtering components moved against the stream by two chains equipped with chain stretcher.

| Business Type | Manufacturer, Exporter, Supplier |

| Country of Origin | India |

| Type | Mechanical Bar Screen |

| Material | Stainless Steel |

| Application | Liquid Separation |

| Color | Silver |

| Feature | Automatic Control, Corrosion Resistant, High Quality, Simple Operation |

| Driven Type | Electric |

| Phase Type | Three Phase |

| Automation Grade | Automatic |

- The Mechanical bar Screen is used to screen sewage water entering the purification plant, and is normally installed in channels.It is composed of a set of filtering components moved against the stream by two chains equipped with chain stretcher.

| Business Type | Manufacturer, Exporter |

| Country of Origin | India |

| Type | Mechanical Bar Screen |

| Material | Stainless Steel |

| Application | Liquid Separation |

| Color | Metallic, Silver |

| Feature | Automatic Control, Corrosion Resistant, High Quality, High Strength, Simple Operation |

| Voltage | 440 |

| Driven Type | Electric |

| Phase Type | Three Phase |

| Automation Grade | Automatic |

- The Mechanical Fine Screen is used to screen sewage water entering the purification plant, and is normally installed in channels.It is composed of a set of filtering components moved against the stream by two chains equipped with chain stretcher.

| Business Type | Manufacturer, Supplier |

| Length | 2000 mm |

| Height | 900 mm to 750 mm |

| Width | 120mm |

| Conveyor bod Material | Ms. Powder coted / SS |

| Screw Type | MS / SS |

| Motors make (Crompton) | 0.5 hp,3 phase (415v ac 50Hz) |

| Tube Shape | Round / U-tube |

A screw conveyor is a mechanism. It uses a rotating helical screw, called “flighting”, that is installed within a tube or trough, to move liquid or granular materials. In many bulk handling industries, they are used. Screw Conveyor is one of the Important Products among Mechanical Conveying Systems to convey bulk materials from one location to another. Every time the screw rotates, A tube- or U-shaped trough acts as the conveying surface around the auger, where powder bulk, granular, and even non-flowing material is pushed along the trough surface. In the screw conveyor’s material is fed through the inlet, passes through the conveyor via the turning auger, and is taken out via the discharge end. Screw conveyors can be designed in a horizontal, vertical, or inclined arrangement